93/206, Canal bank road,

Indira Nagar, Adyar,

Chennai – 600020

To manage different washer sizes efficiently

For consistent quality across all cutting angles

To balance manual control with automation, increasing productivity.

To protect personnel during operation

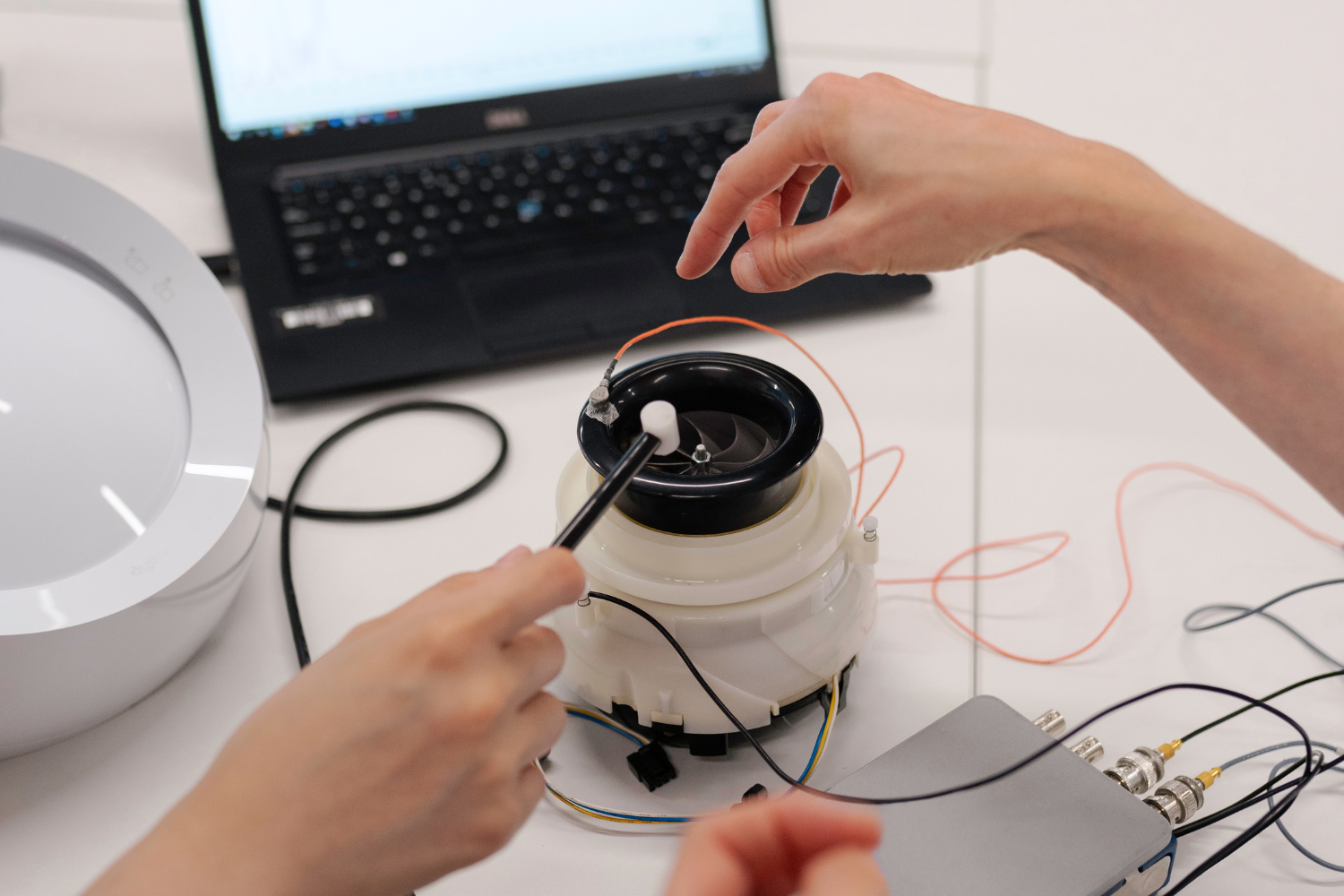

We began by developing comprehensive CAD and mechanical drawings that addressed every nuance of the cutting process. Our focus was on designing an intuitive material clamping system that securely holds washers, allowing for precise engagement with cutting tools

Leveraging state-of-the-art cutting tools and technologies, we engineered the machine to achieve consistent precision at various cutting angles. The system was designed to accommodate different materials without sacrificing performance or safety

Striking a balance between manual input and automation, our system provides operators with control over key parameters while automating repetitive functions. This not only speeds up the process but also minimizes human error and increases overall efficiency

Recognizing the importance of operator safety, every component of our design underwent meticulous evaluation. Safety interlocks, emergency stops, and ergonomic controls have been incorporated to create a secure working environment without compromising on performance

We conducted extensive testing to validate design efficiency and precision. Prototypes underwent real-world trials to assess material clamping integrity and cutting accuracy, with iterative refinements made based on feedback