93/206, Canal bank road,

Indira Nagar, Adyar,

Chennai – 600020

Develop a machine layout that maximizes the efficiency of the electrospinning process while ensuring operator safety and ease of maintenance.

Create a design and manufacturing plan that streamlines production, reduces costs, and minimizes assembly errors.

Ensure that the PLC programming is robust and capable of managing the dynamic processes involved in nanofiber production, from materials handling to process control.

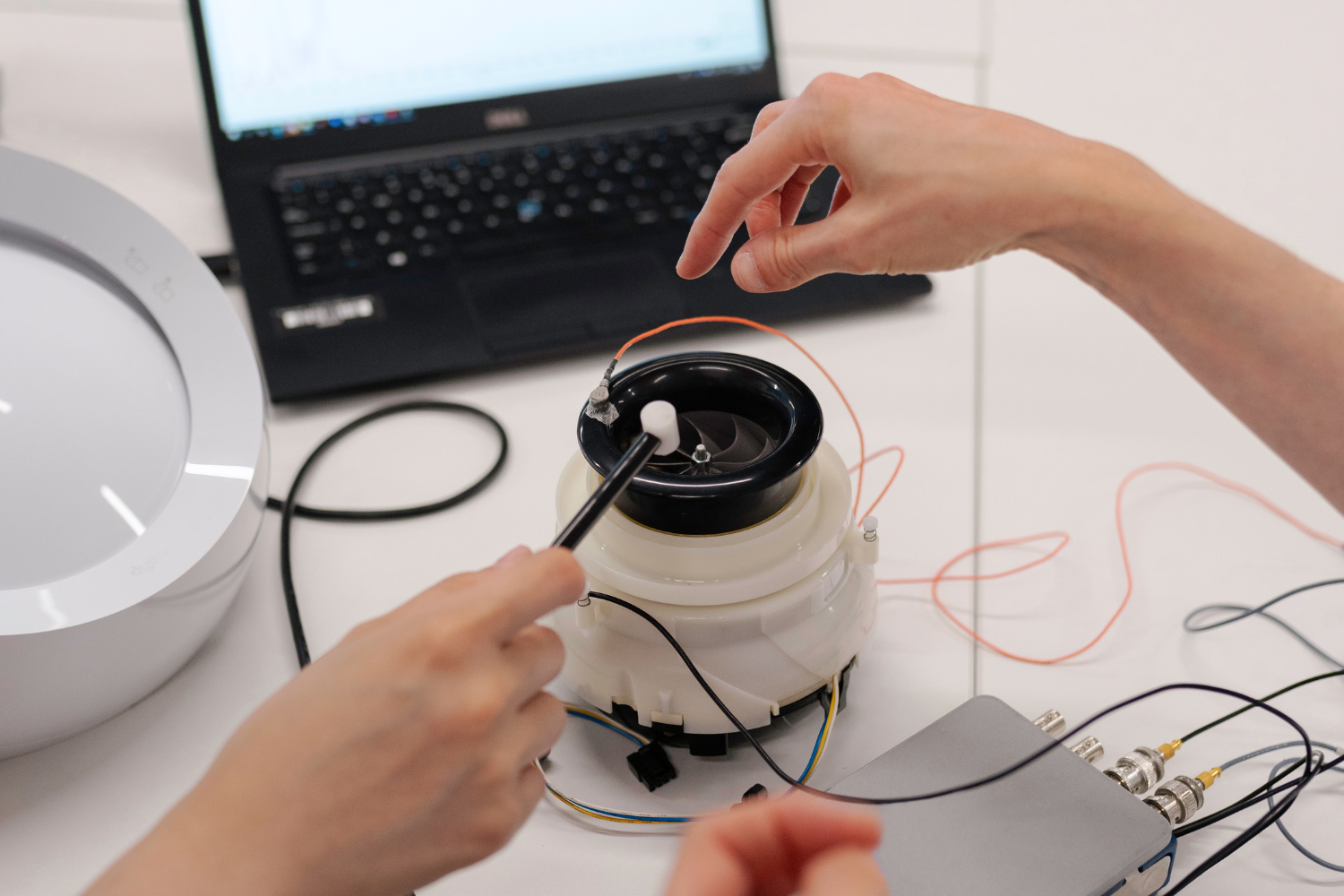

We began by designing the mechanical structure using advanced CAD tools, focusing on creating a system that supports consistent electrospinning performance. Every component, from the polymer feed mechanism to the fiber collection system, was carefully engineered to ensure maximum efficiency and durability.

By optimizing the design for manufacturability, we simplified the assembly process and reduced production costs. Detailed mechanical drawings and clear specifications ensured that every part could be fabricated with tight tolerances, contributing to the overall performance of the machine.

We developed and integrated a full suite of PLC programming tailored to the unique requirements of the electrospinning process. This automation system controls key parameters such as voltage, flow rate, and environmental conditions, ensuring that nanofiber production is both efficient and precise. The control system has been rigorously tested to handle real-time adjustments and fault scenarios, thereby enhancing overall system reliability.

Once assembled, the Espin Nano Machine underwent extensive testing under various operating conditions. These tests confirmed that the system met all performance benchmarks for nanofiber production, and the integrated PLC system ensured smooth, automated operation throughout the process.